From healthcare to fashion, 3D printing has enabled different industries do things never before possible while bringing products to market much faster. Custom-built prostheses, 3D printed toys and everything in between can be created through 3D printing. Today with me in-studio is Cristina Fuser, Product Manager for PQ by Ron Arad, a 3D printed eyewear company. Also joining me from San Diego is Lucy Beard, founder, Chief Cobbler of Feetz, a sustainable, 3D printing company for shoes and Romain Kidd the CEO of MyMiniFactory, a website dedicated to the free sharing of 3D printable files.

From healthcare to fashion, 3D printing has enabled different industries do things never before possible while bringing products to market much faster. Custom-built prostheses, 3D printed toys and everything in between can be created through 3D printing. Today with me in-studio is Cristina Fuser, Product Manager for PQ by Ron Arad, a 3D printed eyewear company. Also joining me from San Diego is Lucy Beard, founder, Chief Cobbler of Feetz, a sustainable, 3D printing company for shoes and Romain Kidd the CEO of MyMiniFactory, a website dedicated to the free sharing of 3D printable files.

CRISTINA FUSER Product Owner for pq by Ron Arad

CRISTINA FUSER Product Owner for pq by Ron Arad

“I come from a marketing background and moved into product because the consumer experience is much more interesting to me.”

“With pq, it was an interesting change. It was my first time working with a product you can touch.”

“The consumer experience at pq is all about the person. It’s not just a product, it’s an experience.”

“Typically you go into a store and try on a million pairs of glasses. At pq we switch it around. We start with a 3D scan of the face with 33 cameras. It’s the same tech used in Hollywood for special effects.”

“The software reconstructs a 3D model of your face in a way that’s dimensionally accurate.”

“Any point of your face that affect the way you wear glasses is scanned.”

“The moment you choose a style those frames are customized to fit your face.”

“We take customization to the next level. You can change the thickness of the bridge, how high you want them to rest.”

“It’s total freedom of customization. We couldn’t do this without 3d printing. We print them one by one without any inventory.”

“The glasses are all one piece.”

“Ron Arad had a vision and dream that our CEO wanted to follow: Ron’s art is beautiful and functional.”

“Ron Arad is incredible. He wants to do things in a completely different way.”

“We use the word anti-ordinary because it’s the same philosophy in our glasses.”

“We people imagine 3D printers they think of tiny printers in your house. We use gigantic oven-like industrial printers. It takes up to 48 hours to print a pair of glasses.”

“People don’t imagine how light things that are 3D printed are. You don’t even feel the glasses on your face.”

“We print out of the UK because our facilities are based there. We do all of the coloring it Italy.”

“We’re opening a pop-up in NYC. Price points are around $200-$250.”

LUCY BEARD CEO of Feetz

LUCY BEARD CEO of Feetz

“I found out about 3D printing a few years ago. Mass customization was what I was looking for.”

“We have an app you can download. Take a photo of your feet with an accuracy of 2 mm.”

“I grew up in England and went to school there. I was good with numbers so my teacher said to be an actuary.”

“As an actuary I took data to predict who was going to live or die. I wanted to meet the people behind my predictions. I knew there was something different. I learned that was that I wanted to be an entrepreneur.”

“I wanted to make a physical product. I knew it was 6 months at least to make something and wanted to change that.”

“I had no clue about 3D printing. I watched a machine at Starbucks make anything you want and decided that the problem of finding the shoes I wanted could be solved with a local maker space.”

“I learned in Chattanooga at a maker space how to 3D print.”

“I started because I couldn’t find a pair of shoes that fit and then I learned how they were made!—An average pair of boots uses 17k liters of water!”

“Materials to make shoes are so bad some are banned in the US.”

“We make 20 billion pairs of shoes of year for only 17 sizes with only 7 billion people on the planet. I thought there had to be a better way.”

“We found all the polymers that were good for shoes and started to make a pair of shoes.”

“We’re not wasting materials, there’s no stock inventory. Everything is recyclable.”

“You should own the whole life cycle of your business. I’m corporately responsible.”

“Shoes can be melted and reused up to 20 times for new shoes.”

“We use little home printers and they are just as durable as any other well-made shoes.”

“The power of being with a community is that you can learn faster.”

“We’ve got vans with 3D printers running so people can make Feetz on the Streetz.”

“Shoes start at $40 t0 $200.”

ROMAIN KIDD CEO of MyMiniFactory

ROMAIN KIDD CEO of MyMiniFactory

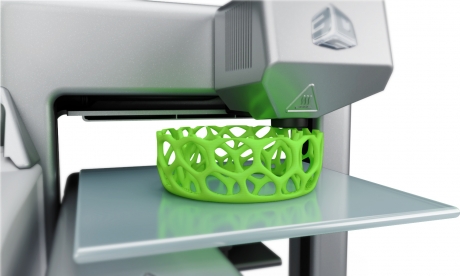

“1 million 3D printers have been sold since 2017. That number is growing at a 50% growth rate every year.”

“We’re building a world where products are shared like you’d share a song.”

“We have thousands of designers on the platform.”

“We focus on affordable 3D printers.”

“As an independent platform, we want to make sure that we’re relevant in the 3D printing space.”

“3D printing is a $100B industry.”

“3D printing an iPhone case or things around your home, decorative items, are very popular.”

Join ‘Dot Complicated with Randi Zuckerberg’ next Wednesday when Marianne Williamson joins the show!! Only on SiriusXM Business Channel 111! 9am PT/12pm ET!